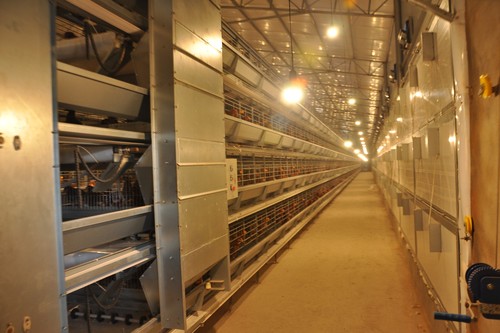

The automatic equipment of H frame layer cage uses international standards. It meets the current and future development trends and requirments of farm automation equipment in China.

The full automatic H frame layer cage system is from Germany. It has the advantages of long service life, high functional reliability, humanized management and operation.

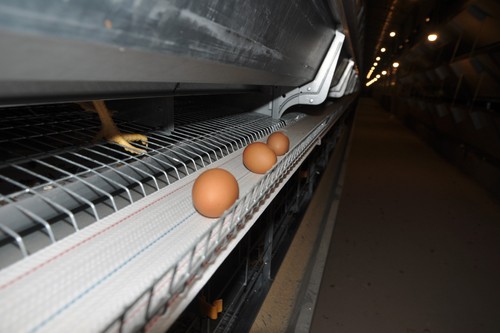

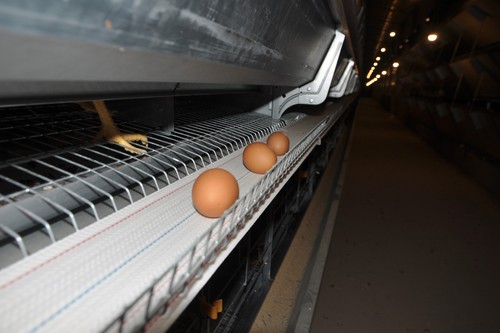

The surface of the wire mesh is fully hot galvanizing, the thickness of the zinc layer is about 400μm, and the anti-corrosion effect is 3-4 times that the general galvanized wire mesh. The entire cage door is a sliding grille that can be easily opened, making the turning of poultry in and out more simple and user-friendly. The egg buffer device can hinder when the egg rolls down quickly, so that the egg can fall on the egg belt safely, minimizing the breakage rate of eggs effectively.

The replaceable bottom mesh increases the convenience of maintenance and the efficient maintenance of the cage mesh system. We choose the wire material with higher toughness to make the bottom mesh rebound slowly after deformation, protecting the quality of the eggs. The nipple drinker are designed on the edge of the partitions mesh, and each chicken can easily reach two nipple drinkers.

Automatic egg collection system plays a very important role in successful layer management.

1. Maximize time and labor cost savings;

2. Reduce contact between humans and chickens, and reduce the chance of cross infection as much as possible;

3. Accurately calculate the number of eggs laid on each tier, each row, and each house, and calculate the cost and chicken production in detail.

4. In order to improve the production efficiency of the farm and reduce the damage of eggs, we provide automatic egg lifting system, multi-layer collection system, platform drive system and manual collection platform.

5. It can achieve seamless connection with egg grading packaging system.

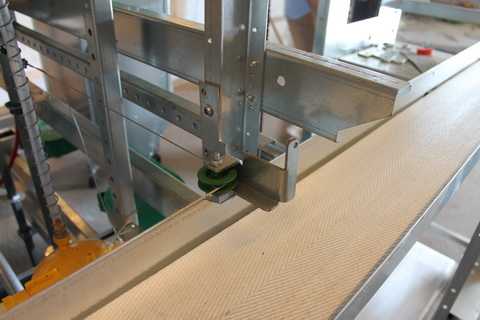

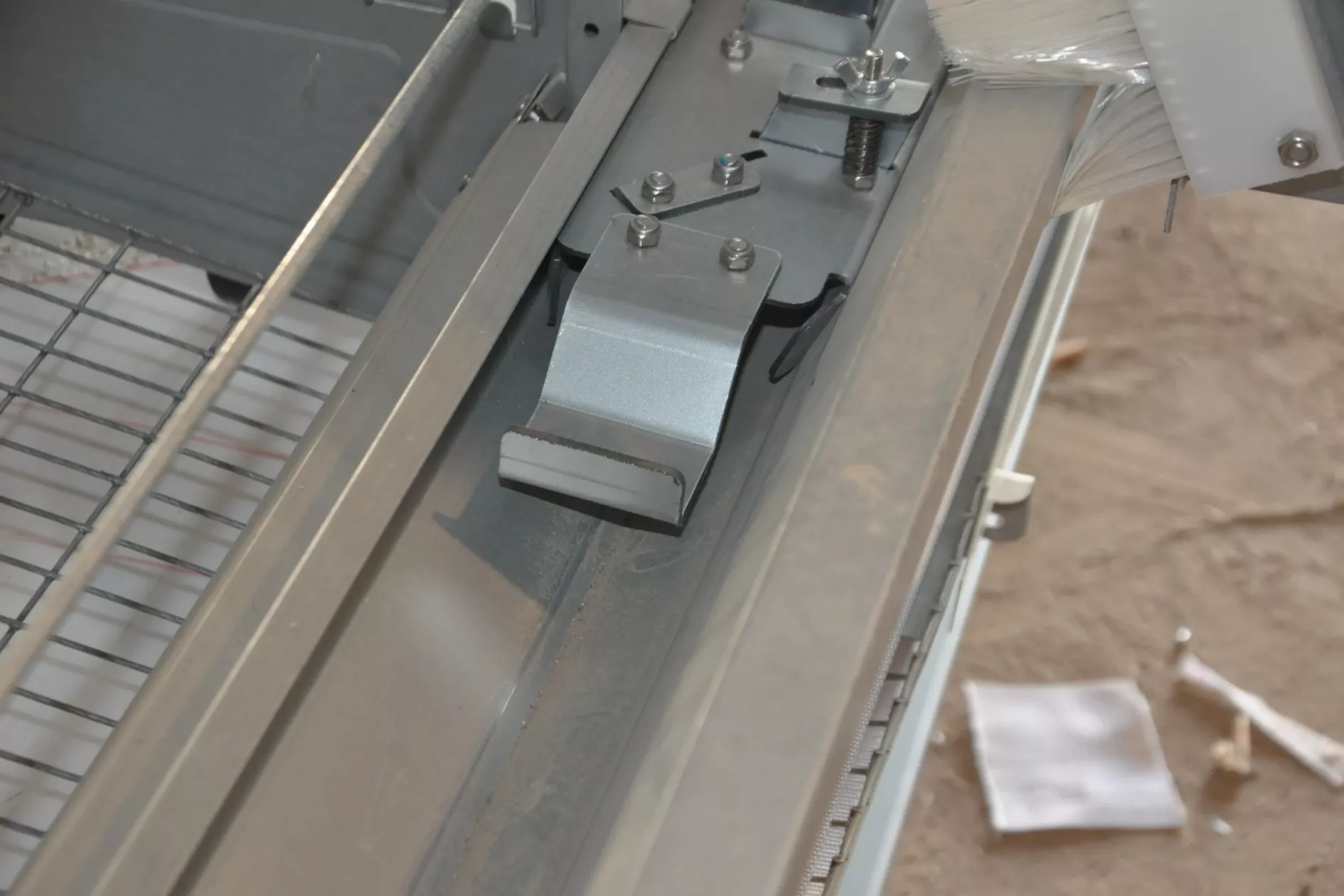

6. Polypropylene tape is the most flexible and adaptable egg collection channel. With the tension device of the egg belt and the flexible egg blocking system, it can effectively ensure that the eggs roll onto the egg collection channel safely, and minimize the breakage rate of eggs.

Using STRONGEST feed chain, the distribution of feed is even and reliable.

Winworld’s STRONGEST chain feeding system can transfer the feed to the poultry smoothly and without separation, ensuring the daily feed intake of each chicken. It cooperates with high-edge feed trough to save feed without sprinkling.

-High operating efficiency

-Low maintenance requirements

-Long service life

Use the driving feeding system

-The structure is simple, the maintenance is convenient.

-The feed is evenly distributed, the feed volume is large.

-Lowest purchase and use costs.

The two optimized feeding methods meet different feeding requirements.

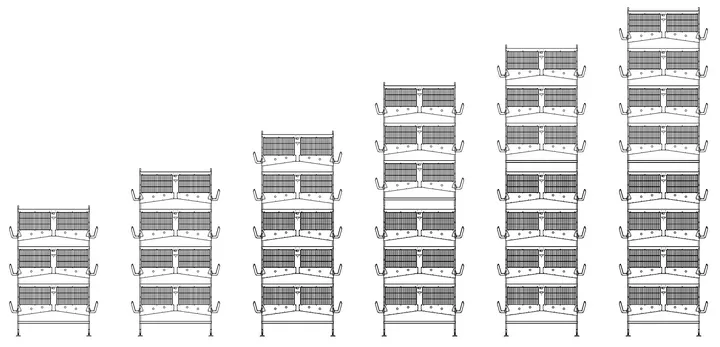

Reasonable equipment construction is the basis for perfect operation.

High-precision production technology and design are used to ensure that the equipment can run normally in the chicken house with a maximum length of 120 meters.

The carefully designed bottom adjustment device can maximize the installation and operation of the equipment on uneven ground, and it is resistant to corrosion.

The deep feed trough can ensure that the chickens will not cause waste when they eat.

The wide cage door structure can ensure flexibility and convenience when handling chickens.

The structure of the cage mesh can ensure that the eggs roll smoothly to the egg belt without being damaged.

Automatic manure removel system.

Manure conveyor-simple, clean, efficient

Polypropylene(PP) manure belts are located underneath the chicken cage to collect manure. Manure can be stored and ventilated on the conveyor belt for a period of 7 days. When removing manure, the manure falls from each tier of manure belt onto the horizontal manure belt. Then it can be transported to the manure storage room or be transported to manure truck through the syncline manure belt.

-Dry manure is a fragile substance, and its nutrient concentration is 5 times that of manure slurry.

-Dry manure is more cost-effective during long-distance transportation;

-The storage space required for dry manure is only 1/3 of the manure slurry, and up to 80% of dry matter can be obtained from dry manure.